ISOLITE Mortars

ISOLITE Mortars

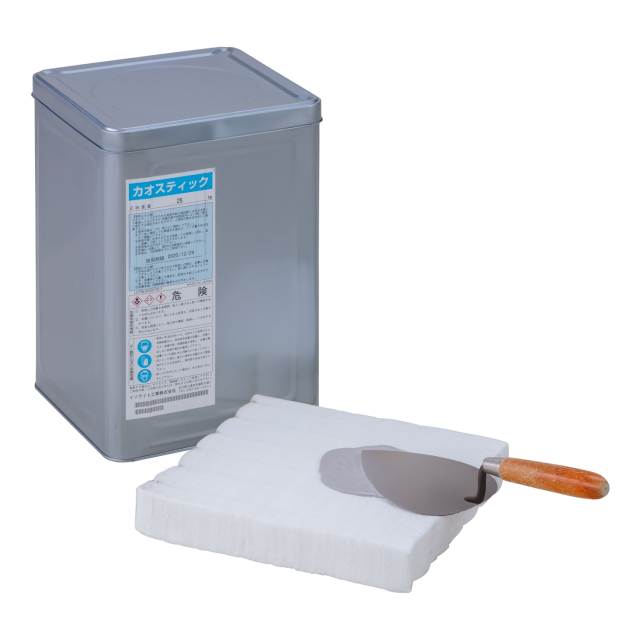

ISOLITE offers a range of Mortars designed to meet your specific requirements for material, density, and porosity levels. These mortars provide excellent fire resistance, exhibiting minimal shrinkage/expansion during drying or sintering. Moreover, they contribute significantly to enhancing construction efficiency.

Specifications

| Product Name |

Grains Size |

Mixing

Water Ratio (%) |

Type of

firebrick tested |

Adhesion

Time (min) |

Modulus of Rupture after adhesion MPa (kgf/cm²) | Unit Weight (kg) | Packaging Type | ||

| (μm) | after drying at 105°C | after drying at 1000°C | |||||||

| ASW (Wet-Type) |

N-10 | 1000 pass | – | B2 | 1〜3 | 0.39 (4) | 0.69 (7) | 25 | Can |

| N-12 | 〃 | – | B4 | 0.39 (4) | 0.69 (7) | ||||

| F-14 | 〃 | – | B5 | 0.69 (7) | 1.1 (11) | ||||

| S-150 | 〃 | – | C1 | 1.8 (18) | 1.8 (18) | ||||

| ASD (Dry-Type) |

N-10 | 〃 | 35 | B2 | 0.59 (6) | 0.98 (10) | Paper bag | ||

| N-12 | 〃 | 34 | B4 | 0.69 (7) | 0.78 (8) | ||||

| F-14 | 〃 | 35 | B5 | 0.79 (8) | 0.89 (9) | ||||

| F-30 | 〃 | 31 | LAP-165 | 1.2 (12) | 1.4 (14) | ||||

| SAS-W | (Wet-Type) | 〃 | – | LBK-23 | 0.49 (5) | 0.69 (7) | Can | ||

| SAS-D | (Dry-Type) | 〃 | 35 | LBK-23 | 0.49 (5) | 0.69 (7) | Paper bag | ||

| HAS-W | (Wet-Type) | 〃 | – | LBK-28 | 0.98 (10) | 1.1 (11) | Can | ||

| HAS-D | (Dry-Type) | 〃 | 30 | LBK-28 | 0.79 (8) | 1.2 (12) | Paper bag | ||

| MAS-W | (Wet-Type) | 〃 | – | ISO-COR | 2.5 (26) | 3.8 (39) | Can | ||

| MAS-D | (Dry-Type) | 〃 | 27 | ISO-COR | 2.1 (21) | 3.4 (35) | Paper bag | ||

| MAS-DS | (Dry-Type) | 〃 | 17 | BAL-99 | 1.1 (11) | 1.4 (14) | |||

| MAS-LS | (Dry-Type) | 〃 | 17 | BAL-99M | 0.78 (8) | 1.4 (14) | |||

| BOARD

MORTAR |

(Dry-Type) | – | 34 | Silica Board | 0.39 (4) | 0.20 (2)* | |||

*after firing at 500°C

■ Adhesion Time indicates the time required to set bricks with 2mm joints until they stop moving.

■ MAS-DS, MAS-LS are heat-set mortars, all others are air-set.

| Product Name | Suitable types of firebrick | Volume estimation for joints (2mm thickness) | ||

| Standard brick

(kg per 1000 pieces ) |

Application area

(kg per 1m²) |

|||

| ASW | N-10 | A1, B1, B2 | 260〜300 | 5.4〜6.2 |

| (Wet-Type) | N-12 | A3, A4, B4 | 260〜300 | 5.4〜6.2 |

| F-14 | A5, A6, B5, B6, C1, C2 | 250〜290 | 5.1〜6.0 | |

| F-15 | A7, C3 | 250〜290 | 5.1〜6.0 | |

| S-150 | C1, C2, C3 | 150〜200 | 3.1〜4.1 | |

| ASD | N-10 | A1, B1, B2 | 180〜220 | 3.7〜4.5 |

| (Dry-Type) | N-12 | A3, A4, B4 | 180〜220 | 3.7〜4.5 |

| F-14 | A5, A6, B5, B6, C1, C2 | 170〜210 | 3.5〜4.3 | |

| F-30 | LAP-165 | 160〜200 | 3.3〜4.1 | |

| SAS-W | (Wet-Type) | LBK-20, LBK-23 | 230〜270 | 4.7〜5.6 |

| SAS-D | (Dry-Type) | LBK-20, LBK-23 | 150〜200 | 3.1〜4.1 |

| HAS-W | (Wet-Type) | A7, LBK-26, LBK-28, LBK-30, LBK-3000, LHB | 250〜290 | 5.1〜6.0 |

| HAS-D | (Dry-Type) | A7, C3, LBK-26, LBK-28, LBK-30, LBK-3000, LHB | 160〜200 | 3.3〜4.1 |

| MAS-W | (Wet-Type) | ISO-COR | 250〜290 | 5.1〜6.0 |

| MAS-D | (Dry-Type) | ISO-COR | 160〜200 | 3.3〜4.1 |

| MAS-DS | (Dry-Type) | BAL-99, BAL-99M | 230〜270 | 4.7〜5.6 |

| MAS-LS | (Dry-Type) | BAL-LS | 230〜270 | 4.7〜5.6 |

| BOARD MORTAR | (Dry-Type) | Silica Board, Super Board | 530〜570* | 5.8〜6.2 |

*Volume required for a 3mm joint for a board sized 610 x 150 mm

■ Above estimations are for 3 out of 6 sides of the brick and do not include reserve material.

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu