ISOWOOL WET FELT

ISOWOOL WET FELT

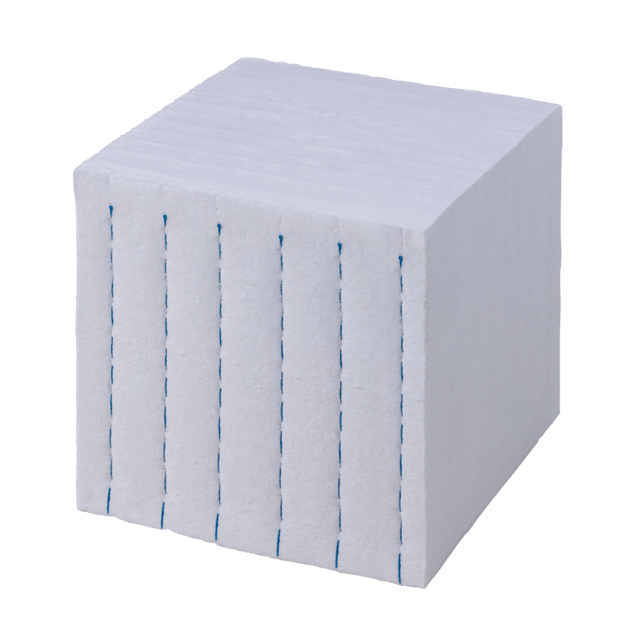

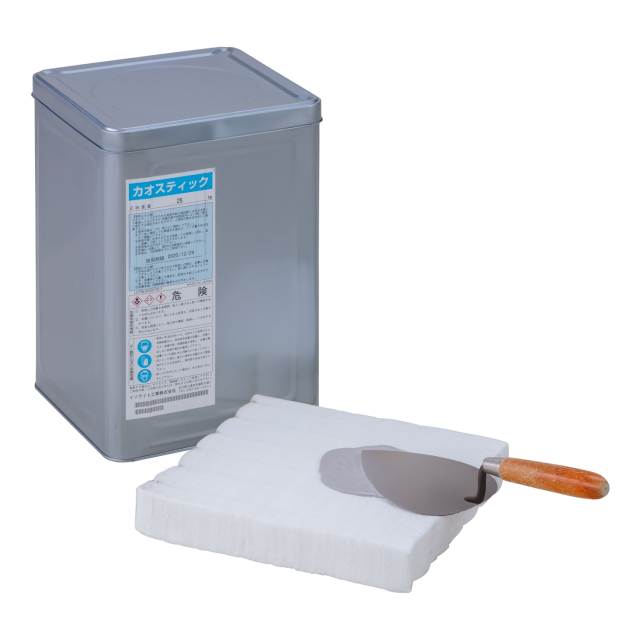

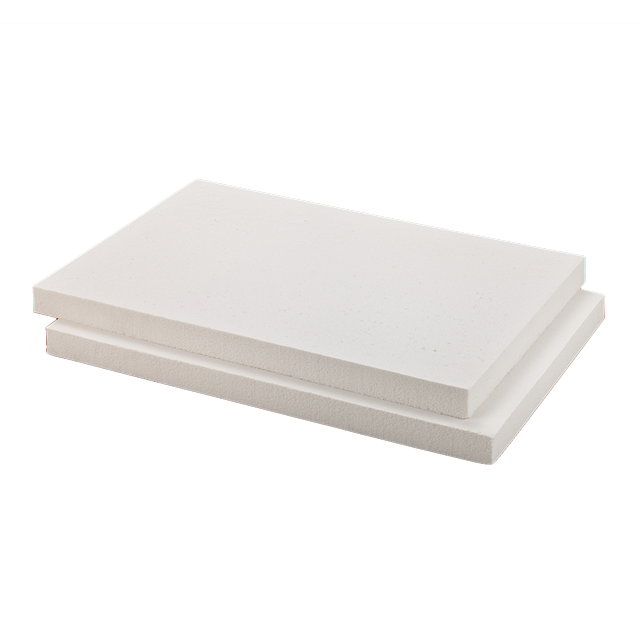

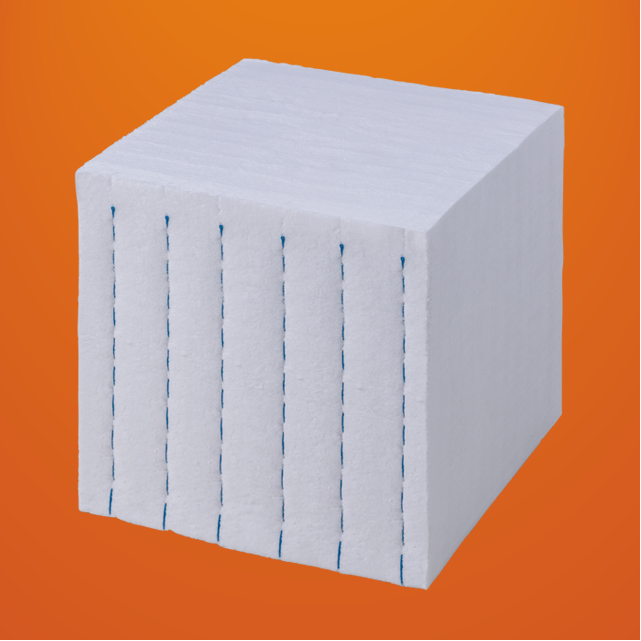

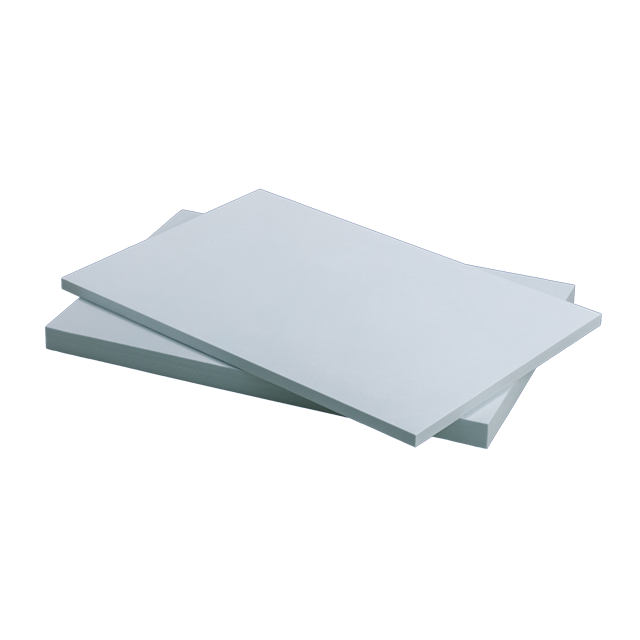

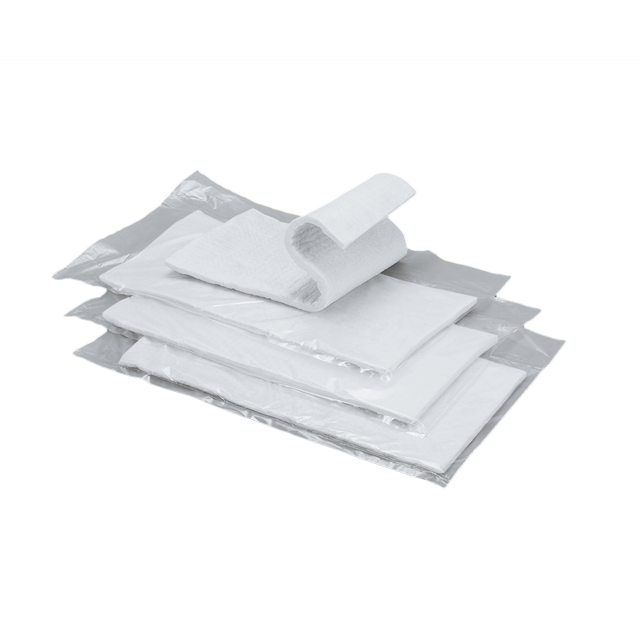

Made from ISOWOOL 1260 BLANKET with inorganic binder of colloidal silica. It is delivered in a plastic bag. Its flexibility and moldability make it applicable to complex shapes, and since it hardens by use of binder after drying, it is applied where furnace-surfaces should be made more solid than blanket, e.g. to withstand higher gas velocity. 1. Air dried, it becomes a light weight insulator which can be sawed, cut or sanded. 2. It is cut into the required shape with scissors or a cutter knife. 3. Though WET FELT is later dried, about 400 kg/m3 in bulk density, it is much heavier during installation due to containing aqueous binder. So the standard size is set as rather smaller 600 x 300 mm.

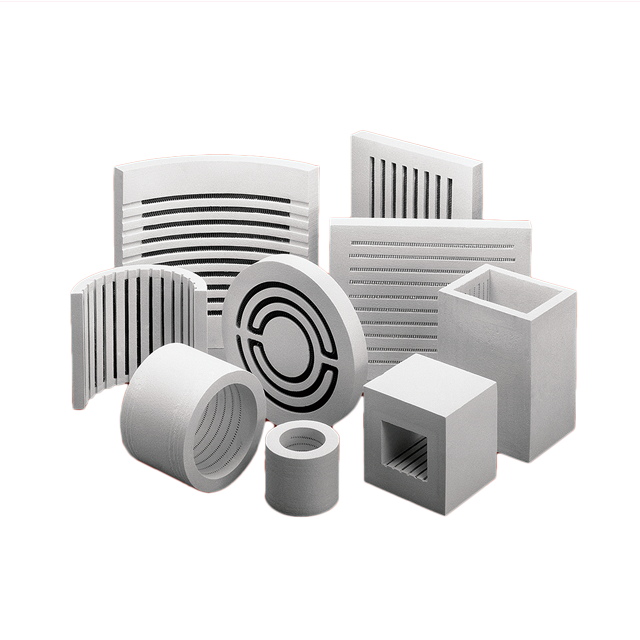

Typical Applications

1. Trough linings for conveying molten metals

2. Hot gas duct linings.

3. Furnace hot face lining in ceramic kiln, box furnace and petrochemical furnace, for high velocity and/or durable insulation.

4. Protection alloy hardware exposed to high temperatures.

Quality

| Properties | WET FELT N | |

| Max. Service Temperature (℃) | 1200 | |

| Bulk Density (kg/m³)

JIS R 3311 |

390

(dried at 105℃) |

|

| Linear Shrinkage (%) at 1,000℃X24hJIS R 3311 |

1.3 | |

| Thermal

Conductivity |

at 400℃ | 0.08 |

| at 600℃ | 0.10 | |

| at 800℃※ | 0.13 | |

| Chemical

Composition (%) JIS R 2216 |

Al₂O₃ | 24.1 |

| Al₂O₃+SiO₂ | 98.8 | |

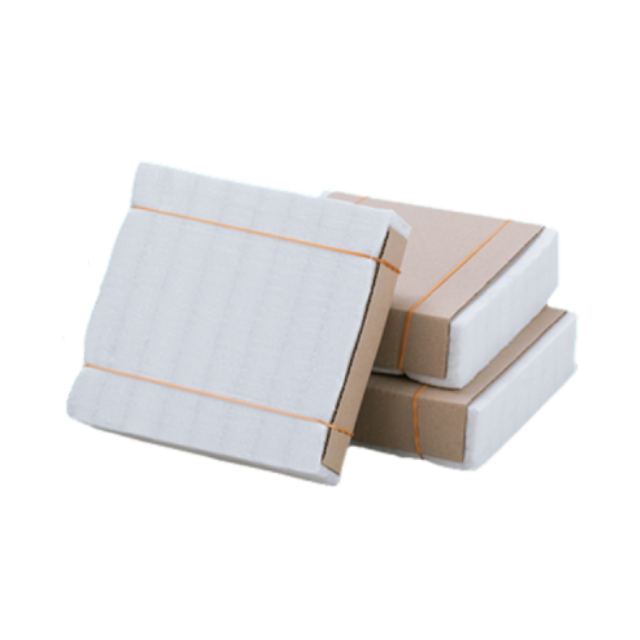

Standard Size and Packaging

| Standard Sizes(mm) | Cardboard Box

Outer Dimension (mm) |

||||||

| Length | Width | Thickness/ Quantity per Carton | |||||

| 3 | 6 | 12.5 | 19 | 25 | |||

| 600 | 300 | 12 | 8 | – | – | – | 628X336X85 |

| – | – | 8 | 6 | 4 | 628X336X135 | ||

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu