ISOFIL

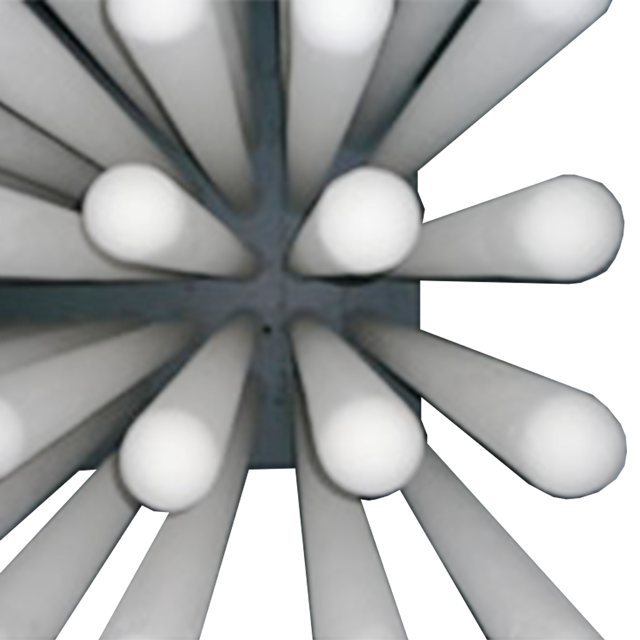

ISOFIL: Heatproof Filter

ISOFIL is a filter for high temperature dust collectors. Developed with high-temperature heat insulation technology and ceramic fibers forming technology by Isolite.

ISOFIL is a heatproof filter and superior to general filters because of its high service temperature up to 900℃, and prevents components of processing system from burning.

And its filtration performance is good very much, and its lifetime is long because its strength doesn’t go down even in high temperature.

We develops, produces and sell the Isofil, and provides the Isofil by cheaper price than our competitors.

Attention

Please mind the Isofil is not all-purpose filter for every dust, and recommend test before introduction into system operation.

Typical Applications

1. Sewage sludge incineration facility

2. Industrial waste incinerators

3. Ash melting furnace

4. Boiler plants

5. Biomass gasification power generation facility

Basic Specification

| ISOFIL IV | ISOFIL N MARK2 | |

| Shape | Candle | Candle |

| Density | 330(kg/㎥) | 250(kg/㎥) |

| Material | Ceramic Fiber | Alumina Fiber |

| Ring pressure strength | 0.8MPa | 1.7MPa |

| Chemical Composition | SiO₂、AL₂O₃ | SiO₂、AL₂O₃ |

Recommended operating conditions

| Filtration wind speed | ≦2[m/min] |

| Pressure loss during operation | ≦2[kPa] |

| Pulse air pressure | ≦4[kg/c㎡] |

| Dust particle diameter | 2〜100[μm] |

| Inlet dust content | ≦30[g/N㎥] |

| Exit gas temperature | ≧150[℃] |

Quality

| ISOFIL | Length | O.D. | Weight | Pressure Loss |

Filtration Area |

Processing gas amount |

| (mm) | (mm) | (kg) | (kPa) | (㎡/PC) | (㎥/hr) | |

| at 1m/mim | at 1m/mim | |||||

| IV-1000 | 1000 | 60 | 0.6 | ≦0.25 | 0.19 | 11.3 |

| IV-1500 | 1500 | 60 | 0.8 | ≦0.25 | 0.28 | 16.7 |

| IV-2000(φ150) | 2000 | 150 | 5.5 | ≦0.5 | 0.94 | 56.4 |

| IV-3000 | 3000 | 150 | 9.0 | ≦0.5 | 1.41 | 84.8 |

| N MARK2 | 2000 | 150 | 4.7 | ≦0.2 | 0.94 | 56.4 |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu