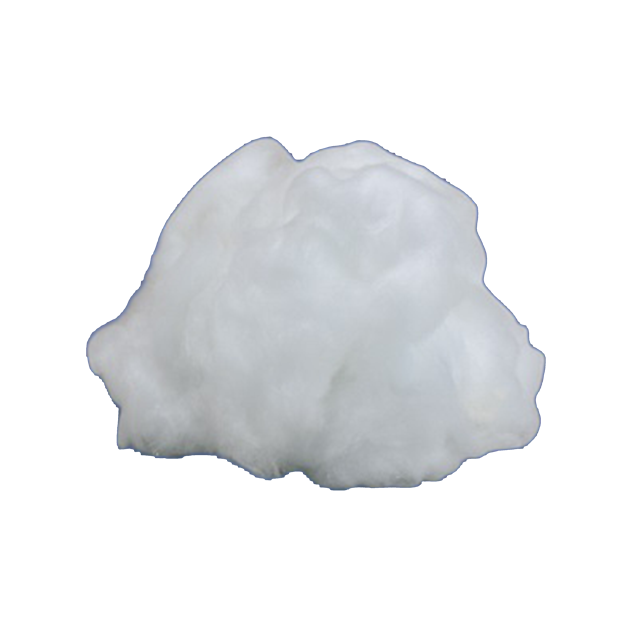

ENGINEERED FIBER COMPOSITE MATERIAL

Description

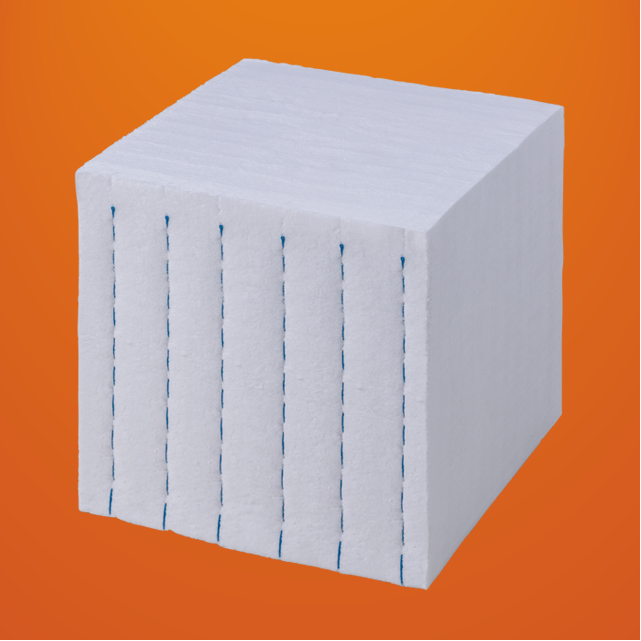

Engineered fiber is an inorganic fiber composite material that can express excellent characteristics when added to raw materials.

The fiber length can be adjusted from 20 μm to 1000 μm to suit various applications.

The fiber index (fiber content) can be increased to 99% by removing the shot (non-fibrous particles) present in the product.

Application

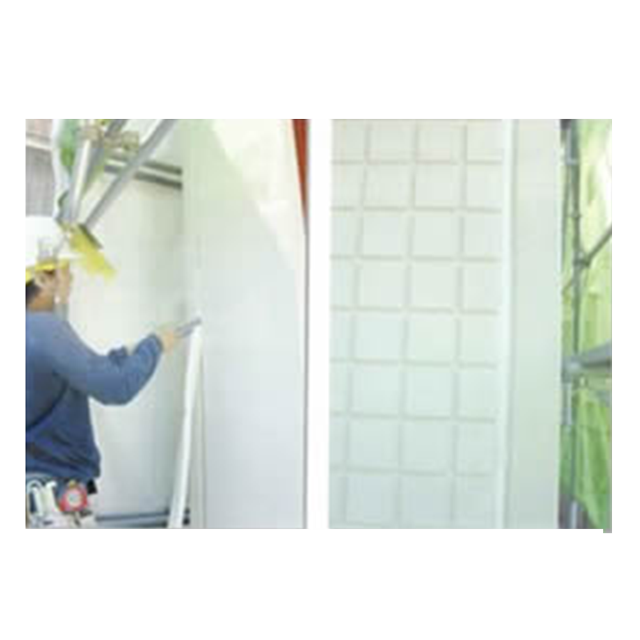

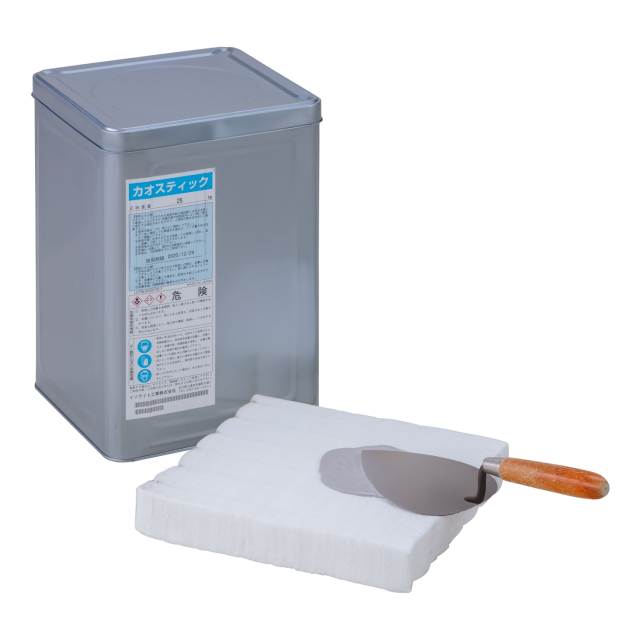

1. friction materials

2. ceramic materials

3. paints

4. adhesives

5. coating and molding agents

Characteristics

1. Inorganic fiber

2. Heat resistance (maximum operating temperature: 1260 to 1600℃)

3. Average fiber diameter 2-6㎛

4. Large surface area due to fiber shape

5. Lighter weight and reinforcement effect of added products

6. High hardness

Quality

| Product Name | 1260 Grade | BSSR 1300 Grade | 1400 Grade | 1600 Grade | |

| Max. Service Temperature (℃) | 1260 | 1300 | 1400 | 1600 | |

| Fiber Diameter(μm) | 2~4 | 2~4 | 2~4 | 4~6 | |

| Fiber Length(μm) | 20~1000 | 20~1000 | 20~1000 | 20~1000 | |

| Crystalline Phase | Amorphous phase | Amorphous phase | Amorphous phase | Polycrystalline Mullite | |

| Chemical

Composition (%) |

Al₂O₃ | 48 | – | 31 | 72 |

| SiO₂ | 52 | 77 | 53 | 28 | |

| ZrO₂ | – | – | 16 | – | |

| CaO+MgO | – | 20 | – | – | |

| Others | – | 3 | – | – | |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu