RCF Free type Tapping

RCF Free Tapping

ISOTAP(Dry)/F tamp (Wet)

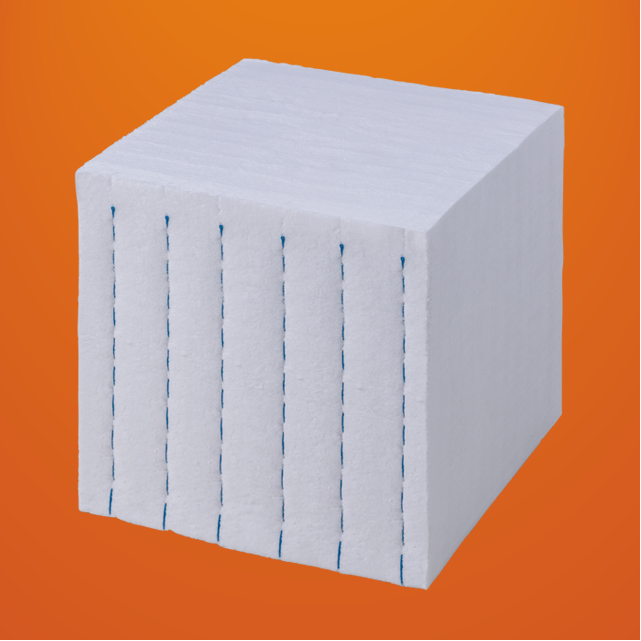

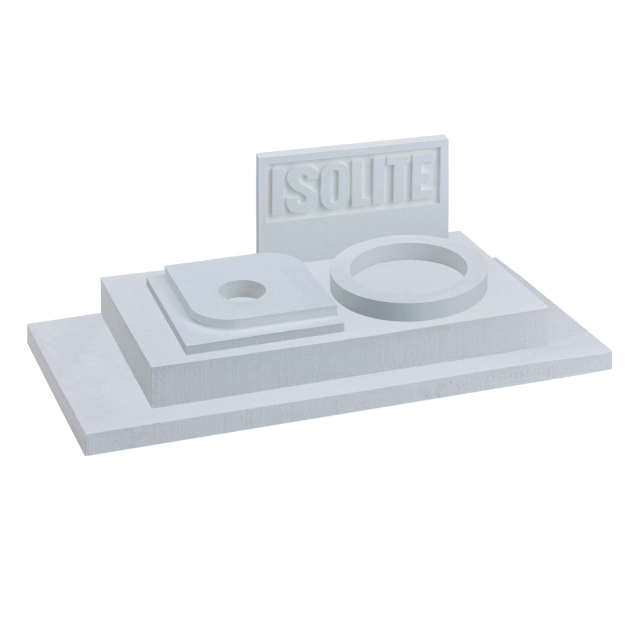

ISOTAP(Dry)and F TAMP (Wet) are heat insulating castable consisting of refractory fibers and refractory grains.

ISOTAP is lighter and more effective in heat insulation

than ordinary castable refractory and plastic refractory.

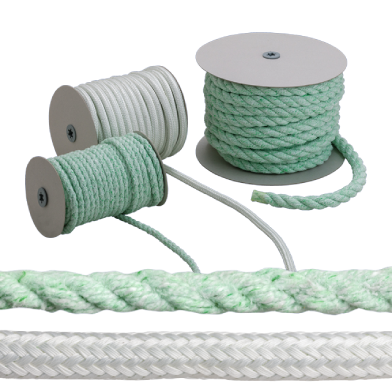

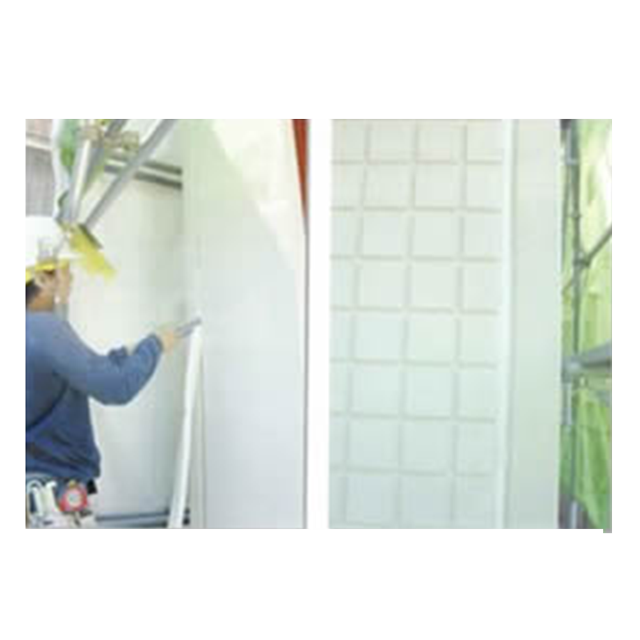

Used as lining material,

because of its good adhering property,

to the industrial heaters

where hard to install High Temperature Insulation Wool products.

- ISOTAP can be installed easily and made into various shapes

Suitable to daubing and tapping installation. - ISOTAP F-12A and F-14A are dry type and hydraulic setting materials.

Mixed with water and becoming hard.

like ordinary castable refractory in room temperature - They are lighter and better in heat insulation

than ordinary castable refractories. - They have high strength.

in spite of their major constituent of High Temperature Insulation Wool. - ISOTAP has high volume stability at drying and heating.

- The fibrous material contained in these products is

exempt from the German Technical Rules for Hazardous Substances (TRGS 905)

F TAMP is wet type heat insulating castable.

Typical Applications

- Skid pipe insulation of reheating furnace

- Hot air duct insulation

- Other general heat insulation

Quality

| DRY type | ISOTAP

F-12A |

ISOTAP

F-14A |

|

| Max. Service Temperature(℃) | 1200 | 1400 | |

| Bulk Density (kg/m³) | After drying at 105℃ | 910 | 1,110 |

| after firing at Max.service.Temp. | 890 | 1,000 | |

| Modulus of Rupture (MPa) | After drying at 105℃ | 0.7 | 0.6 |

| after firing at Max.service.Temp. | 1 | 0.8 | |

| Linear Shrinkage (%) | after firing at Max.service.Temp. | 0.8 | 0.4 |

| Thermal Conductivity (W/(m・K)) JIS A1412-1 |

at 350℃ | 0.22 | 0.28 |

| Chemical Composition(%) | SiO₂ | 36 | 15 |

| Al₂O₃ | 45 | 79 | |

| Water rates recommended (%) | 80~100 | 60~70 | |

| Quantity required (ton/m³) | 0.89~0.92 | 0.86~1.00 | |

| Quantity per Bag(kg) | 15 | ||

| Packaging | Paperbag | ||

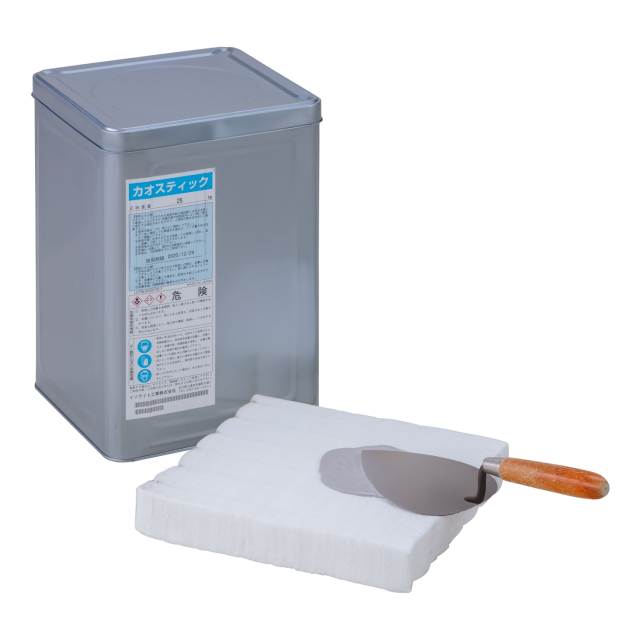

| Wet type |

F tamp 16W

|

|

|

Max. Service Temperature(℃)

|

1600

|

|

| Bulk Density (kg/m³) | After drying | 750 |

| after firing at Max.service.Temp. |

705

|

|

| Modulus of Rupture (MPa) |

After drying

|

1.3 |

|

after firing at Max.service.Temp.

|

2.0

|

|

| Linear Shrinkage (%) |

After drying

|

0.0 |

| after firing at Max.service.Temp. |

-0.3

|

|

| Thermal Conductivity (W/(m・K)) |

at 800℃

|

0.26

|

|

at 1000℃

|

0.31

|

|

|

Chemical Composition(%)

|

Al₂O₃

|

74

|

|

SiO₂

|

26 | |

|

Quantity per plastic container (kg)

|

15

|

|

|

Packaging

|

Can | |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu