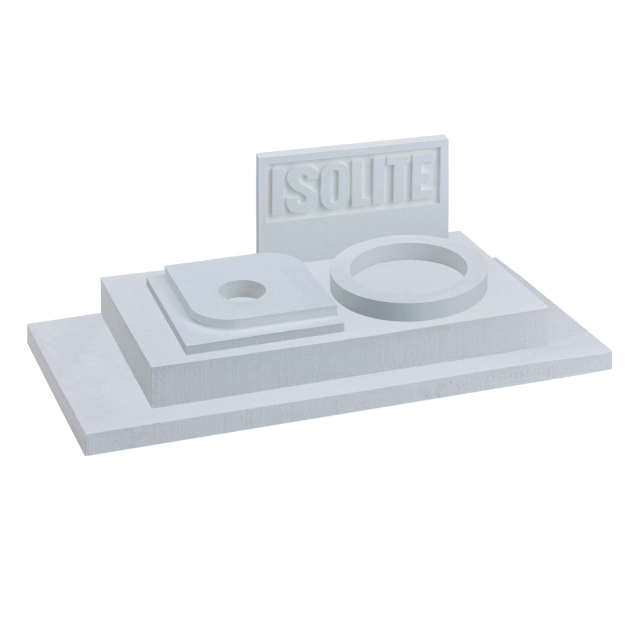

FIBERMAX MODULE

RCF FREE:PCW(Polycrystalline Wool) Module

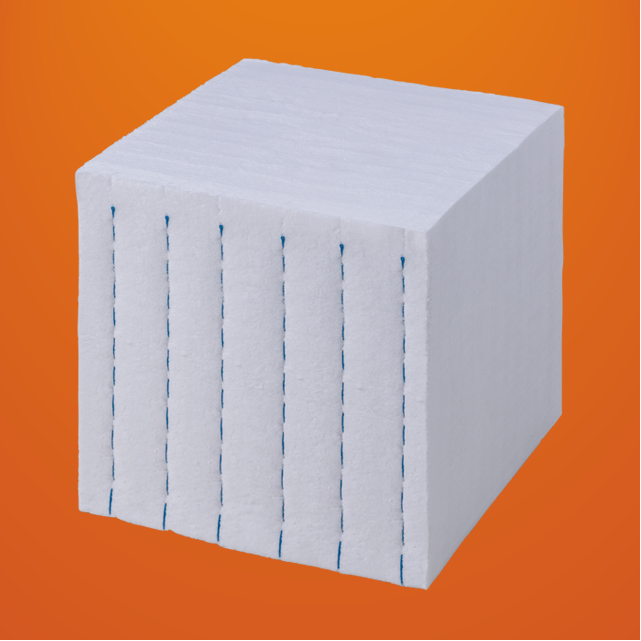

FIBERMAX UNIBLOK and SABER BLOC are PCW module made from FIBERMAX BLANKETs. UNIBLOK is the cut-and-layered type module made of stack strip of blankets while SABER BLOC is the folded type module made of folded blanket.

The cubic structure greatly saves the installation time.

With the same quality of material used, UNIBLOK and SABER BLOC lining can extend service temperature range due to compress and increase bulk density of the module.

ISOLITE can supply various shapes and sizes of module.

UNIBLOK and SABER BLOC lining doesn’t expose metal fittings inside the furnace, and attains fairly high resistance to gas velocity.

Module Types

| Module Types | Anchor Type | |

| UNIBLOK | Module made of cut and tightly compressed BLANKETs | M, T |

| SABER BLOC | Accordion-like module made of a folded and

layer compressed BLANKET |

M, T |

| D BLOCK | Module made of cut and sewn BLANKETs | B, S1 |

Dimensions Guide:

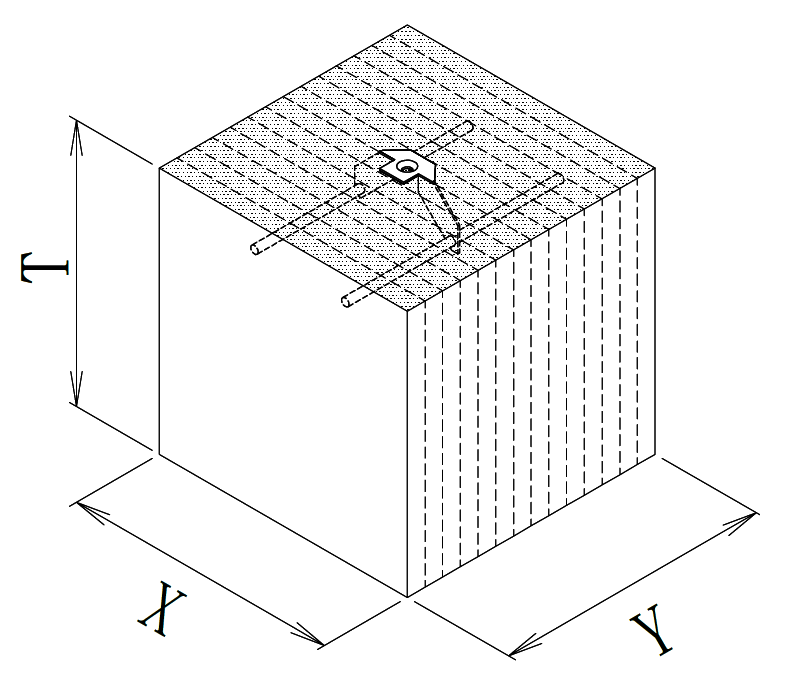

T: thickness X: width Y: stacking direction

(T) mm ⅹ (X) mm ⅹ (Y) mm

・Custom shapes require a drawing.

Anchoring System

For UNIBLOK and SABER BLOC

TYPE-S:Stud-bolt is welded to the shell. Module is inserted and fixed to the anchoring system with a nut and washer.

TYPE-M:Anchoring system is incorporated into the module. Module is fixed to the stud-bolt with a special nut from the inner face of the furnace.

TYPE-T:Anchoring system is incorporated into the module. Module is fixed by attaching a nut from the outer face of the furnace.

For D BLOCK

TYPE-B:Anchoring system is incorporated into the module. Module is fixed to the special stud-bolt by fastening a special nut from the inner face of the furnace.

TYPE-S1:Anchoring system is incorporated into the module. Module is fixed by attaching a nut and washer from the outer face of the furnace.

Quality

| Product Name | 1600

UNIBLOK |

1600

SABER BLOC |

1600D BLOCK | |||

| Max. Service Temperature (°C) | 1600 | 1600 | 1600 | |||

| Bulk Density (kg/m³) | 130 | 130 | 100 | 130 | 170 | |

| Thermal Conductivity (W/(m・K)) JIS A1412–1 *Calculation value |

at 600°C | 0.19 | 0.19 | 0.21 | 0.19 | 0.17 |

| at 800°C* | 0.27 | 0.27 | 0.30 | 0.27 | 0.24 | |

| at 1000°C* | 0.38 | 0.38 | 0.42 | 0.38 | 0.34 | |

| at 1200°C* | 0.51 | 0.51 | 0.57 | 0.51 | 0.46 | |

| Linear Shrinkage (%) | at 1400°C×24h | – | – | 0.7 | 0.5 | 0.4 |

| at 1500°C×24h | 1.1 | 1.1 | 0.9 | 0.7 | 0.7 | |

| Chemical

Composition (%) |

Al₂O₃ | 72 | 72 | 72 | 72 | 72 |

| Al₂O₃+SiO₂ | 100 | 100 | 100 | 100 | 100 | |

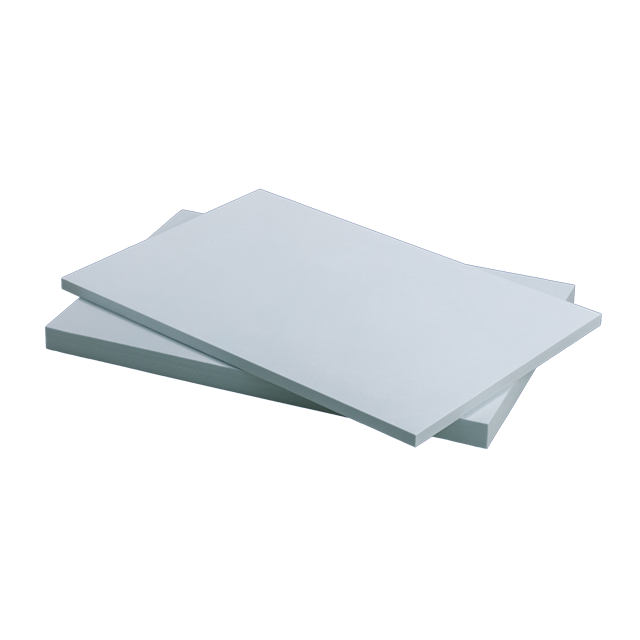

UNIFELT-B

FIBERMAX UNIFELT-B made of FIBERMAX BLANKET thereof cut into rectangular pieces and piled into layers in the same manner as FIBERMAX UNIBLOK. The size of FIBERMAX UNIFELT-B is 300×300 or 200x200mm and the thickness is 50 or 75mm. For ordinary use, 50mm thick is standard.

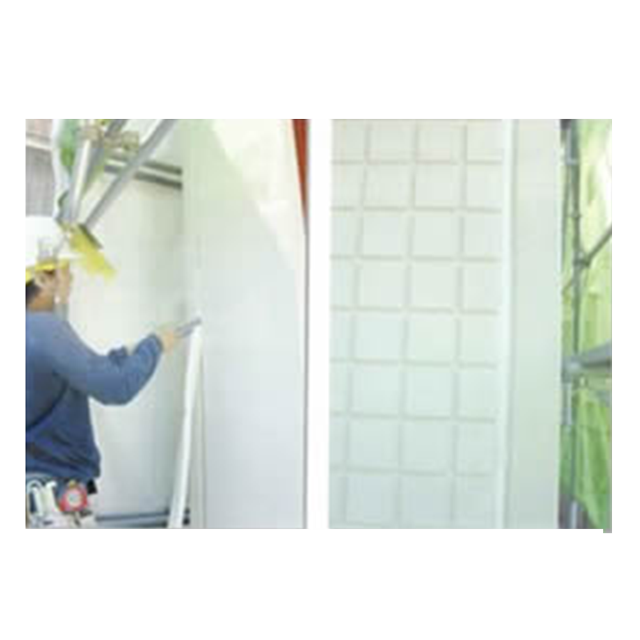

Veneering means the installation of Ceramic Fiber on existing refractories in a furnace. It is an effective method of inner insulation of furnace to reduce heat loss. As for installation, studs are embedded in Fire Bricks, Castables, or Plastics inside the furnace to fix the liners, or KAOSTICK is used to fix the linings, or both methods are applied at the same time.

The greatest merit of veneering is that it reduces heat storage and heat flow by inner insulation. Particularly, when applied to a batch-type furnace, in which the temperature changes very often, it displays a noticeable effect. Veneering has been widely employed because it attains economization of energy without relining the furnace, and recently applied to newly built furnaces, too.

| FIBERMAX | 1600 UNIFELT-B | |

| Max. Service Temperature(℃) | 1600 | |

| Bulk Density (kg/m³) | 130 | |

| Thermal Conductivity (W/(m・K)) JIS A1412-1 ※Calculation value |

at 600℃ | 0.19 |

| at 800℃※ | 0.27 | |

| at 1000℃※ | 0.38 | |

| Linear Shrinkage (%) | at 1500℃×24hrs | 1.1 |

Standard Size (mm)

| FIBERMAX | Thickness | Width | Length |

| 1600 UNIBLOK, SABER BLOC | 100・200・300 | 300 | 300 |

| 1600D BLOCK | 30 | 200 | 150 |

| 50 | 300 | 150・300 | |

| 100・150・200・250・300 | 300 | 300 | |

| 1600 UNIFELT-B | 50・75 | 300 | 300 |

| 200 | 200 |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Q&A

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu