NEOKOTE(Coating materials)

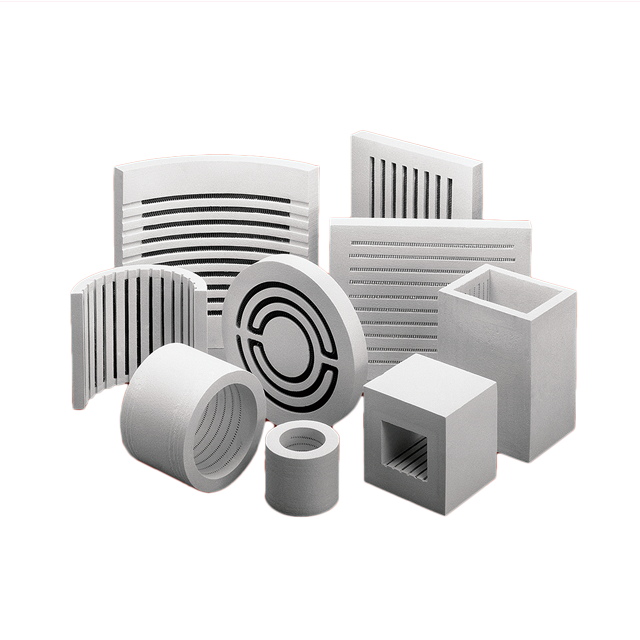

NEOKOTE

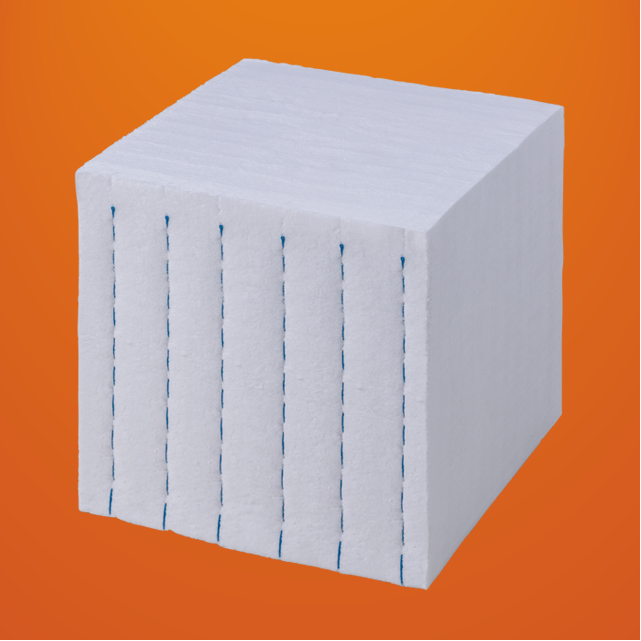

Coating Materials for Ceramic Fiber

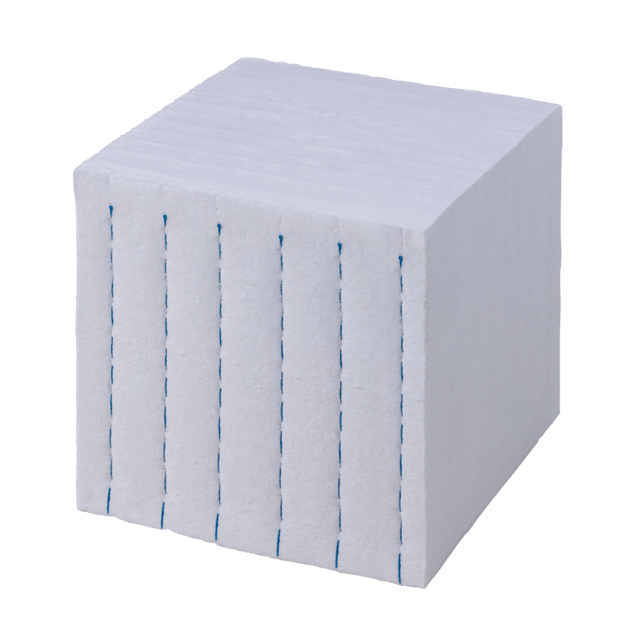

Surface coating for fiber protection plays an important role in block lining of high temperature furnaces. Suitable materials are selected by talking operating conditions into consideration.

Purposes of coating

The purposes of this coating on the ceramic fiber surface are as follows:

- To reduce shrinkage of ceramic fiber during high temperature heating. Surface coating not only increases ceramic fiber surface strength but controls distortion (change of volume) caused by initial shrinkage of ceramic fiber occurring at around 800-1000℃.

- To increase resistance of ceramic fiber to permeation of combustion gases and gases in the furnace, and resistance to corrosion and scale attach.

- To increase resistance of ceramic fiber to gas velocity and abrasion

Quality, Standard Size and Packaging

| NEOKOTE | L | M | S | K | M I | |

| Max. Service Temperature(℃) | 1000 | 1400 | 1450 | 1450 | 1400 | |

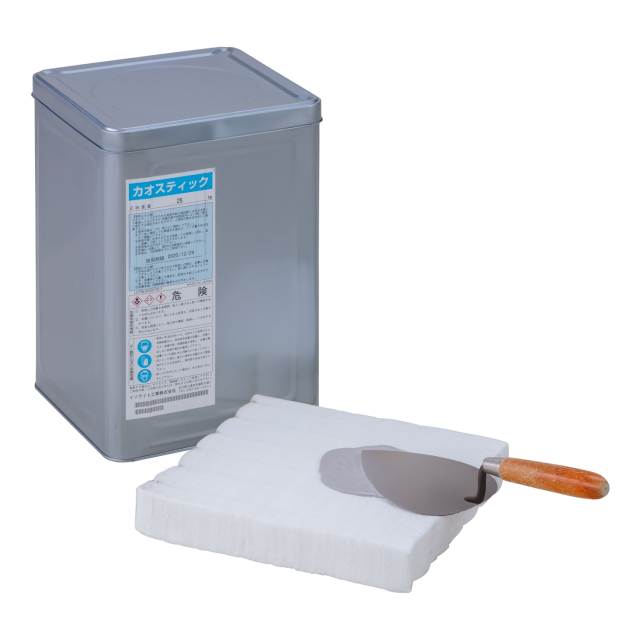

| Type | Dry | Dry | Dry | Dry | Wet | |

| Bulk Density at powder (g/cm³) | 0.75 | 1.10 | 1.04 | 0.87 | 2.00 | |

| Water used in mixing for spray(%) | 60~65 | 40~45 | 40~45 | 45~50 | – | |

| Linear change (%) | After firing at 800℃ | -1.0 | – | – | – | – |

| After firing at 1000℃ | -0.3 | – | – | – | – | |

| After firing at 1300℃ | – | -0.3 | -0.3 | – | -0.3 | |

| After firing at 1400℃ | – | -0.4 | – | – | -0.4 | |

| After firing at 1450℃ | – | – | -0.4 | -0.5 | – | |

| Chemical Composition (%) |

Al₂O₃ | 72 | 66 | 79 | 80 | 87 |

| SiO₂ | 20 | 22 | 20 | 3 | 12 | |

| Others | R₂O 1.2 | SiC 8.0 | – | MgO 15 | – | |

| Quantity Required(kg/m²) Installation thickness:1-2mm |

2~3 | 3~4 | 3~4 | 3~4 | 5~6 | |

| Quantity per Bag or Can(kg) | 20 | 20 | 20 | 20 | 20 | |

| Packaging | Paper Bag | Paper Bag | Paper Bag | Paper Bag | Can | |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu