ISOWOOL VFS

ISOWOOL VFS

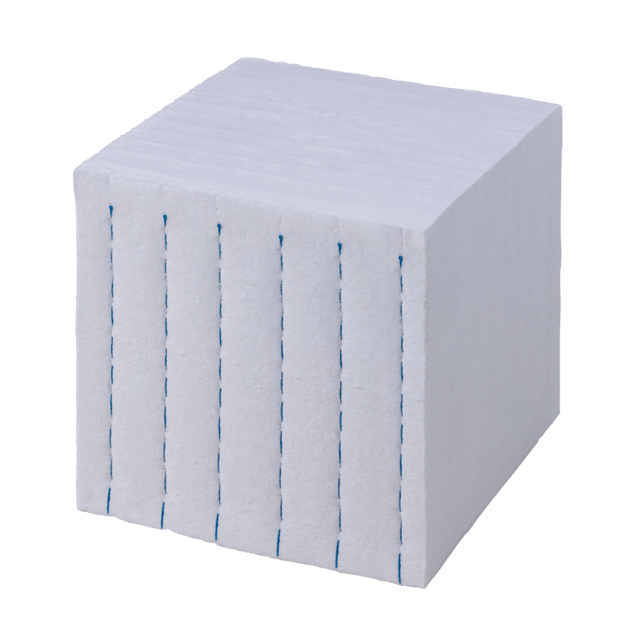

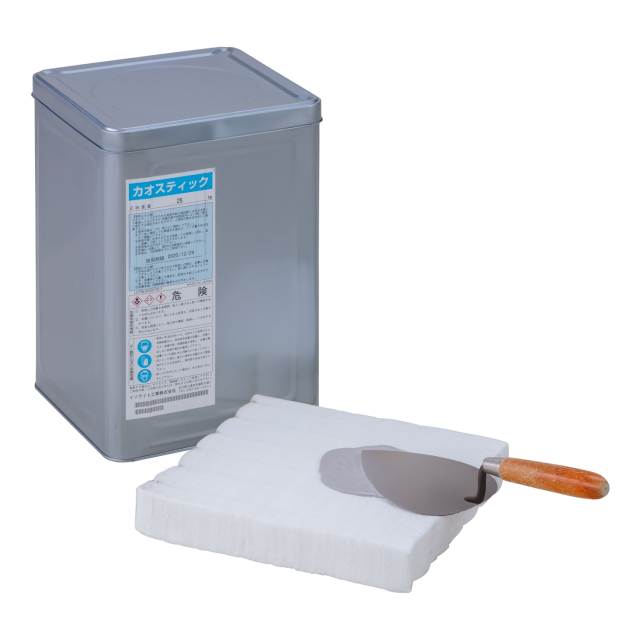

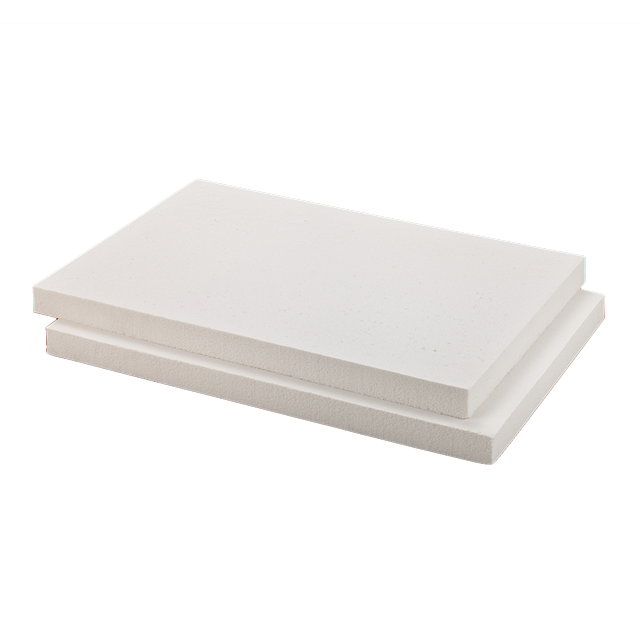

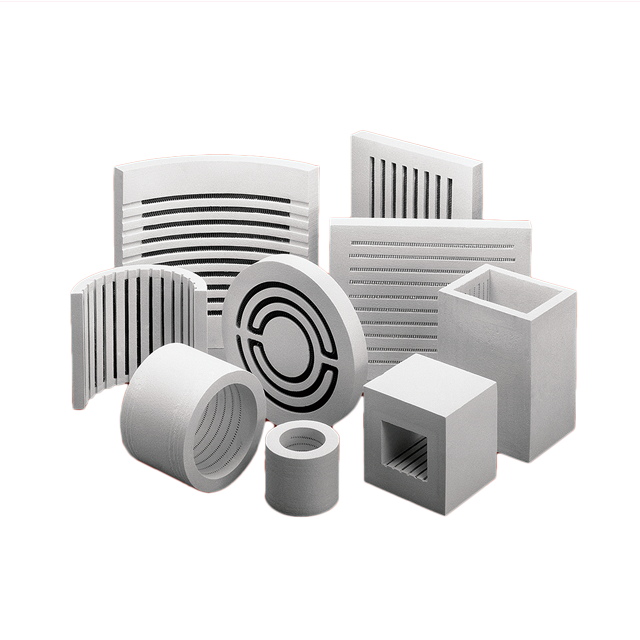

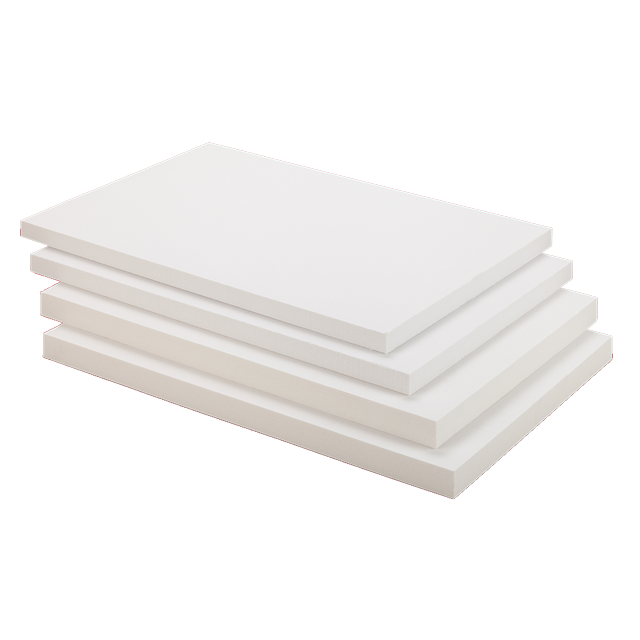

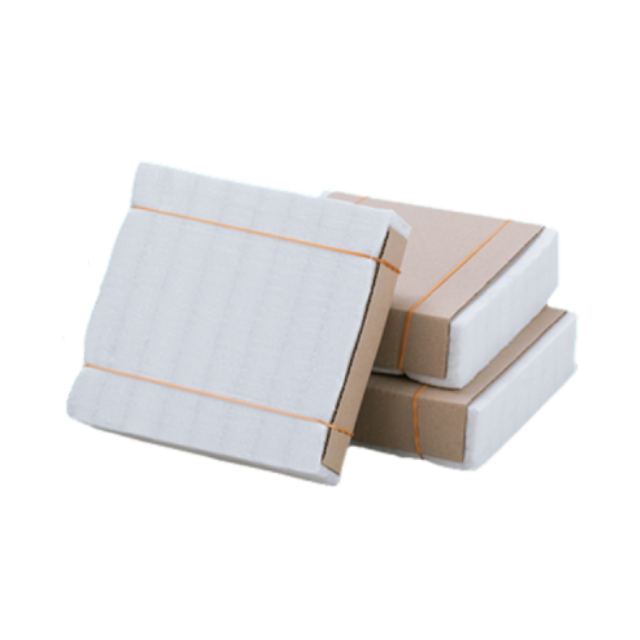

Slurry made of ISOWOOL BULK, inorganic binder, a tiny amount of organic binder, and water is molded and dried to make VFSs in a variety of forms such as flat plates, sleeves, cones, etc. With its non-wettable characteristic to the melting metals, high melting point, heat insulation property and durability, VFSs are used in the sections to have direct contact with the melt in aluminum molding and processing processes

Typical Applications

1. Tap-out-corn for melting aluminum

2. Riser sleeves, Hot tops

3. Combustion chambers of water boiler

4. Hot face lining of electrical furnace

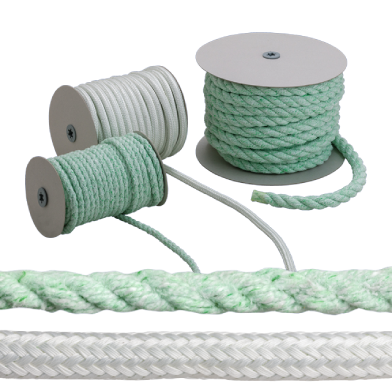

5. Burner block, Peephole tile

6. Riser pipe and Skid-pipe of reheating furnace

7. Insulating cover for Continuous casting nozzle

8.High temperature gasket and packing

SLEEVE C:

Insulating pipe special for riser sleeve or riser system of special steel and non-ferrous metals.

Quality

| 1260 VFS | 1400 VFS | 1600 VFS | SLEEVE C | ||

| Max. Service Temperature(℃) | 1260 | 1400 | 1600 | 1260 | |

| Bulk Density (kg/m³) | 250 | 250 | 180 | 300 | |

| Modulus of Rupture(MPa) | 0.49 | 0.49 | 0.20 | 1.47 | |

| Loss on Ignition (%) at 1100X5h | 6 | 4 | 5 | 5 | |

| Linear Shrinkage (%) at( ℃)X24h |

1.7 (1100℃) |

1.4 (1200℃) |

1.2 (1400℃) |

1.7 (1100℃) |

|

| Thermal

Conductivity |

at 400℃ | 0.09 | – | – | 0.09 |

| at 600℃ | 0.12 | 0.12 | 0.13 | 0.12 | |

| at 800℃※ | 0.16 | 0.16 | 0.20 | 0.16 | |

| at 1,000℃※ | – | 0.23 | 0.28 | – | |

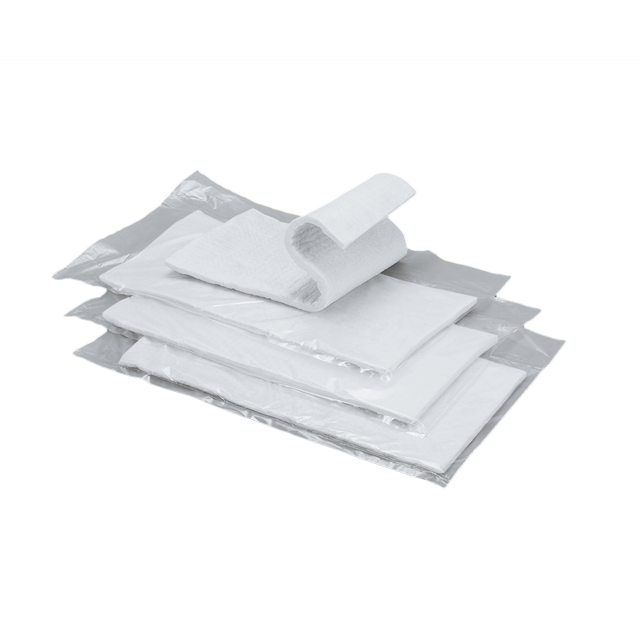

Packaging

According to the shapes.

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu