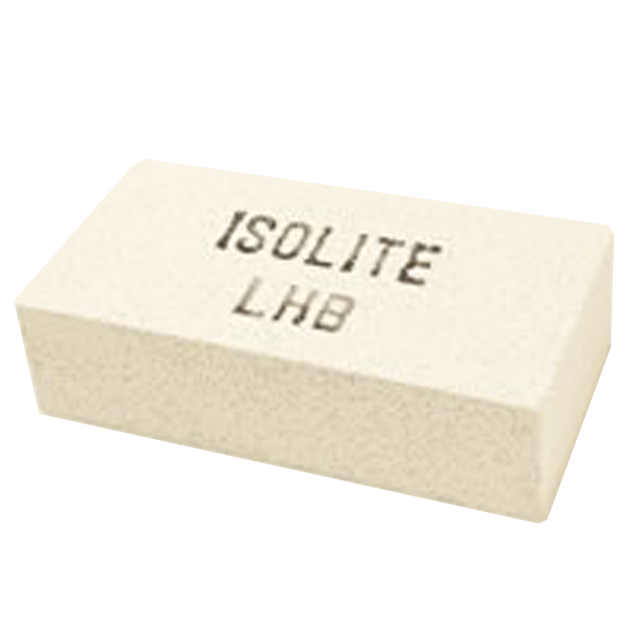

ISOWOOL BOARD

ISOWOOL BOARD

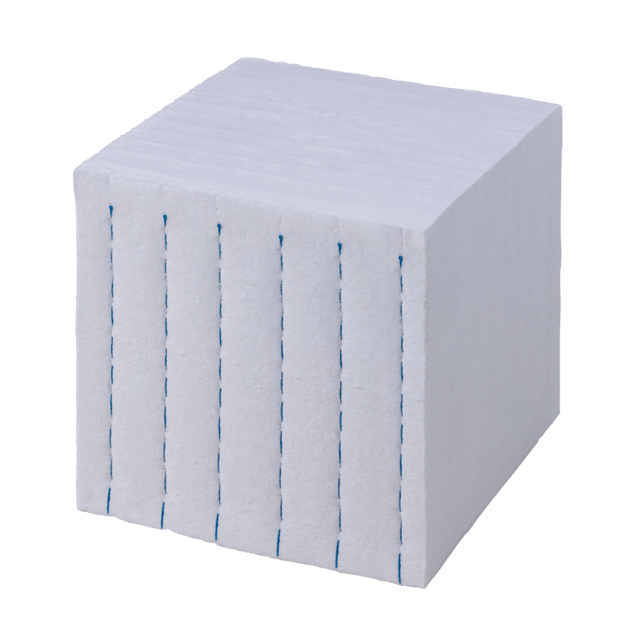

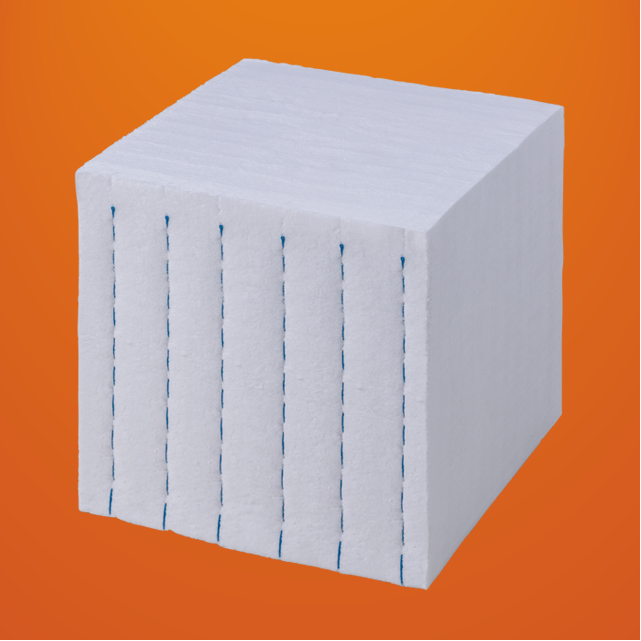

ISOWOOL BOARD is high-temperature insulating boards vacuum formed using ISOWOOL bulk fiber, organic and inorganic binders.

This product will be able to available in rapid heating rapid cooling condition by “suppressing against intensity changes in high-temperature”, “lightweight” and “excellent heat impulsivity”.

Also it has high mechanical strength as compared with other insulation materials.

It can be used for hot face expose lining and backup lining for various furnaces.

Typical Application

Hot-face expose and back-up lining of industrial furnaces.

Quality

| ISOWOOL | 1260 BOARD |

1260 D3 BOARD |

1400 BOARD |

1400 D3 BOARD |

H BOARD HMT |

|

| Max. Service Temperature(℃) | 1260 | 1260 | 1400 | 1400 | 1400 | |

| Bulk Density (kg/m³) | 250 | 320 | 250 | 300 | 1700 | |

| Loss on Ignition (%) | 6 | 5 | 4 | 4 | 3 | |

| Linear Shrinkage (%) at( ℃) × 24hrs |

2.4 (1200℃) |

2.5 (1200℃) |

2.4 (1400℃) |

3.0 (1400℃) |

3.4 (1200℃) |

|

| Thermal Conductivity (W/(m・K)) JIS A1412-1 ※Calculation value |

at 600℃ | 0.12 | 0.12 | 0.12 | 0.11 | 0.34 |

| ※at 800℃ | 0.16 | 0.17 | 0.16 | 0.15 | 0.37 | |

| ※at 1000℃ | 0.23 | – | 0.23 | 0.20 | 0.38 | |

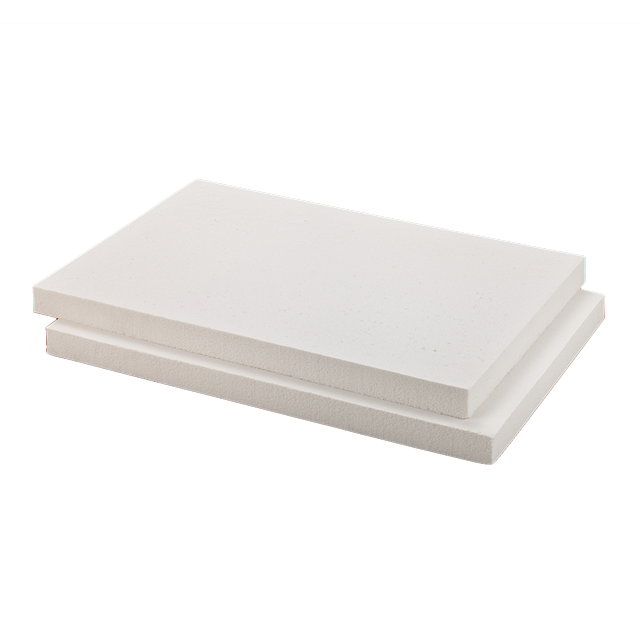

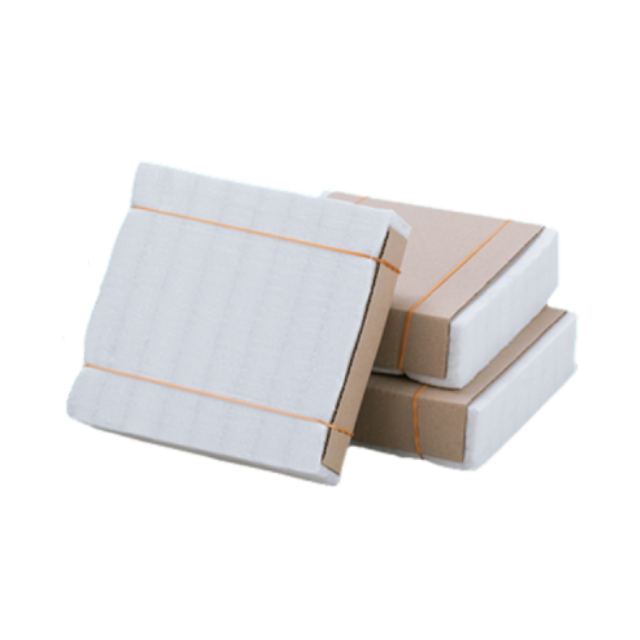

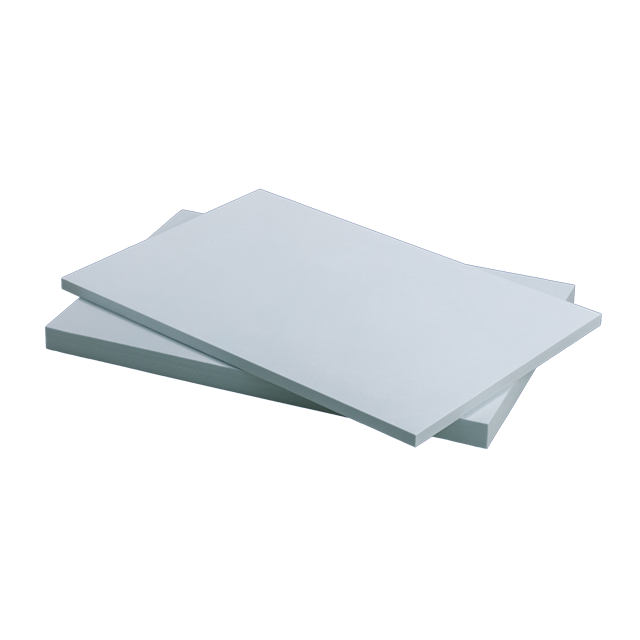

Standard Size (mm)

| Thickness | Width | Length |

| 25,50 | 600 | 900 |

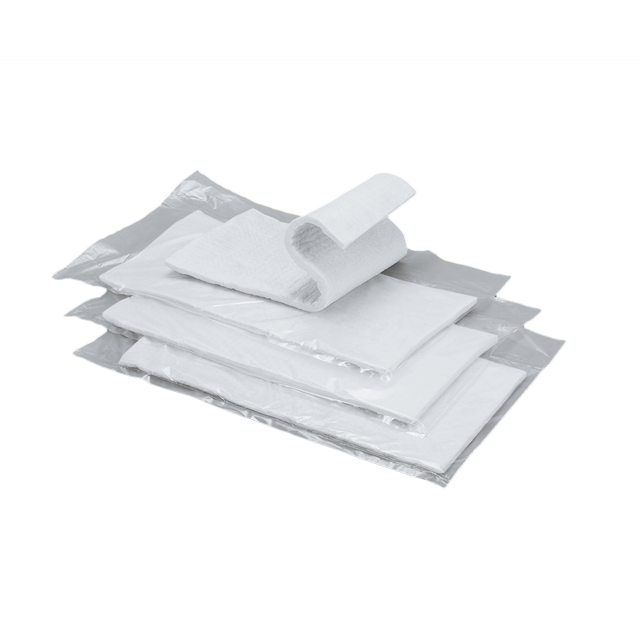

Packaging

| Size(mm) | Q’ty

per carton |

Carton | ||

| Thickness | Width | Length | Size | |

| 25 | 600 | 900 | 4 | 950X640X120 |

| 50 | 600 | 900 | 2 | |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu