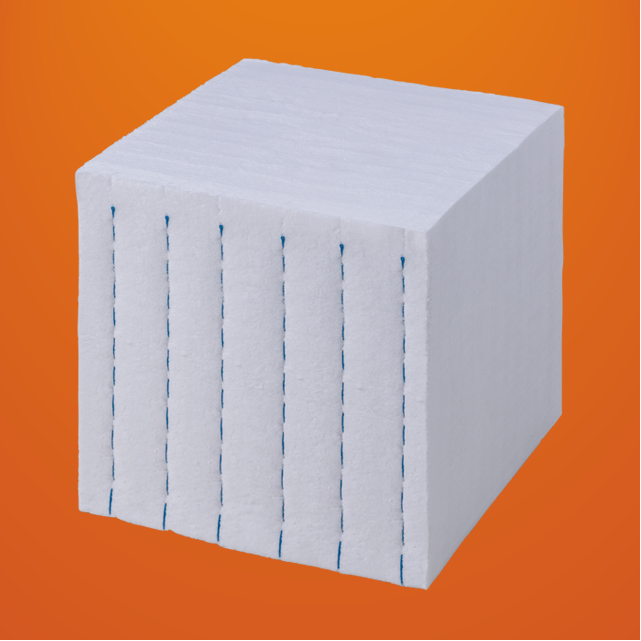

ISOWOOL BSSR BOARD

RCF FREE:Board of AES(Alkaline Earth Silicate) Wool

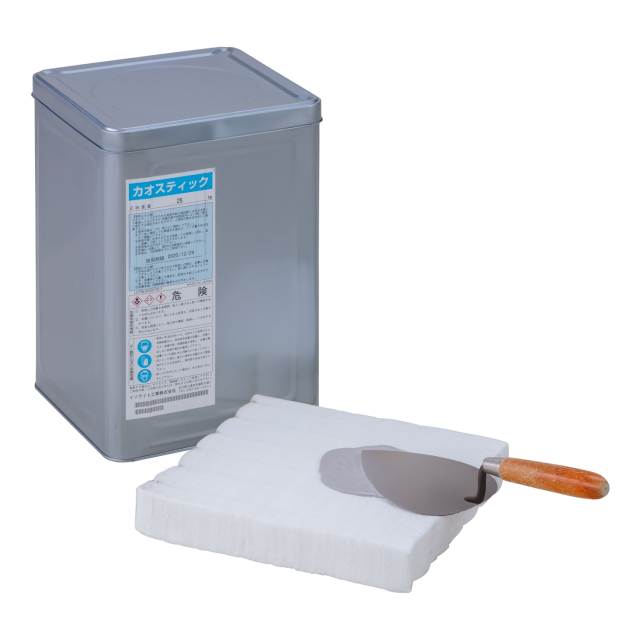

ISOWOOL BSSR BOARDs are vacuum-formed high-temperature insulating boards using Alkaline Earth Silicate (AES) wool, organic and inorganic binders.

It can be used as a lining and backup material for various firing furnaces (high-temperature electric furnaces and so on.)

Product Information

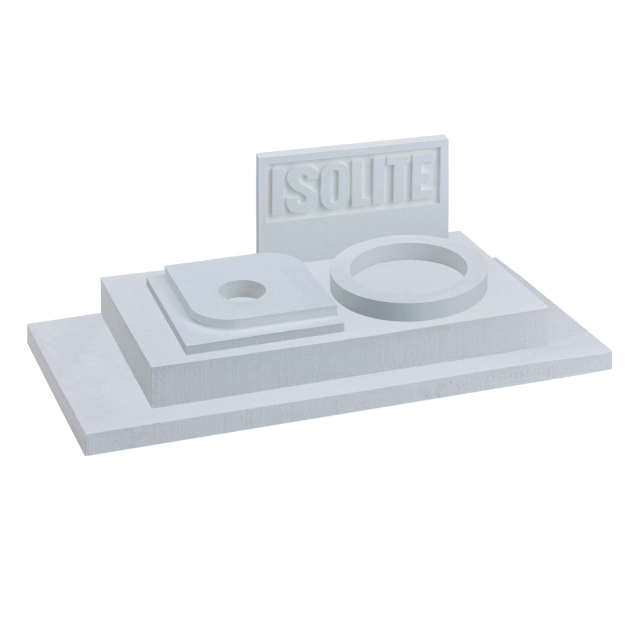

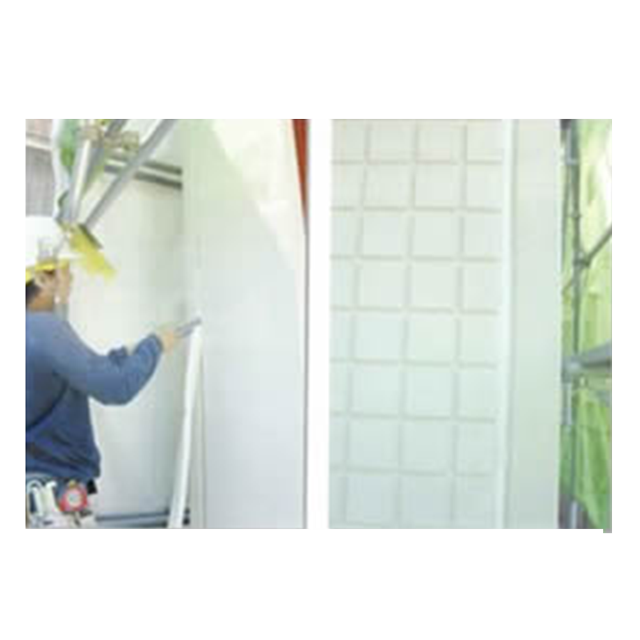

Typical Application

Industrial furnace hot face lining thermal insulation, Back-up lining thermal insulation

(Industries: steel, nonferrous metals, glass, ceramics, petrochemicals, semiconductors, cement, etc.)

【Note】

Isowool BSSR products are subject to rapid changes in volume (shrinkage) due to their thermal history and chemical composition. When making an inquiry, please describe your operating conditions and other relevant information.

Quality

| Product Name | BSSR 1200

BOARD |

BSSR 1200 HD

BOARD |

BSSR 1300

BOARD |

BSSR 1400

BOARD |

|

| Temperature Grade (°C) | 1200 | 1200 | 1300 | 1400 | |

| Bulk Density (kg/m³) | 250 | 340 | 330 | 270 | |

| Loss on Ignition (%) at 1000°C×5h | 4 | 4 | 4 | 3 | |

| Modulus of Rupture (Mpa) | 0.7 | 0.9 | 0.9 | 0.7 | |

| Thermal

Conductivity (W/(m ・ K)) JIS A1412–1 *Calculation value |

at 400°C | 0.09 | 0.08 | 0.08 | – |

| at 600°C | 0.12 | 0.12 | 0.10 | 0.12 | |

| at 800°C* | 0.18 | 0.16 | 0.12 | 0.17 | |

| at 1000°C* | – | – | – | 0.22 | |

| Linear

Shrinkage (%) |

at 1100°C×24h | 1.5 | 1.5 | – | – |

| at 1200°C×24h | – | – | 2.7 | – | |

| at 1300°C×24h | – | – | – | 2.1 | |

| Chemical

Composition (%) |

SiO₂ | 73 | 73 | 77 | 82 |

| CaO+MgO | 22 | 22 | 19 | 16 | |

| Others | 5 | 5 | 4 | 2 | |

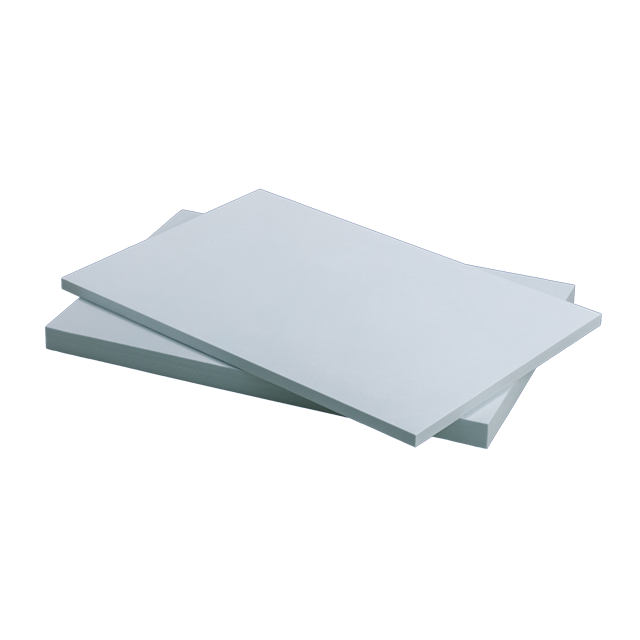

Standard Size

| Thickness | Width | Length | |

| ISOWOOL BSSR 1100Board, HD Board | 25、50 | 600 | 900 |

| ISOWOOL BSSR 1300 Board |

Packaging

| Size(mm) | PC per

carton |

Carton | ||

| Thickness | Width | Length | Size | |

| 25 | 600 | 900 | 4 | 950X640X120 |

| 50 | 600 | 900 | 2 | |

Data shown are typical values obtained in accordance with accepted test methods.

They are provided for your reference only and are subject to change without notice.

Q&A

Catalog

Contact

【Call】

Branch Office: Overseas Department,

Tokyo, Osaka, Nagoya, Kyushu